Space Tribology Consulting, Inc.

Providing expert consulting on tribological issues, including vacuum lubrication and the chemistry and materials properties of interfaces and coatings

Demonstrated and Trusted Track Record in the Space Industry

Jeff Lince, Ph.D., President of Space Tribology Consulting, Inc., has over 35 years experience assuring the success of spacecraft by providing robust tribological materials solutions throughout the vehicle life cycle: during design and manufacturing phases, or anomaly resolution including root cause analysis, followed by producing an effective outcome.

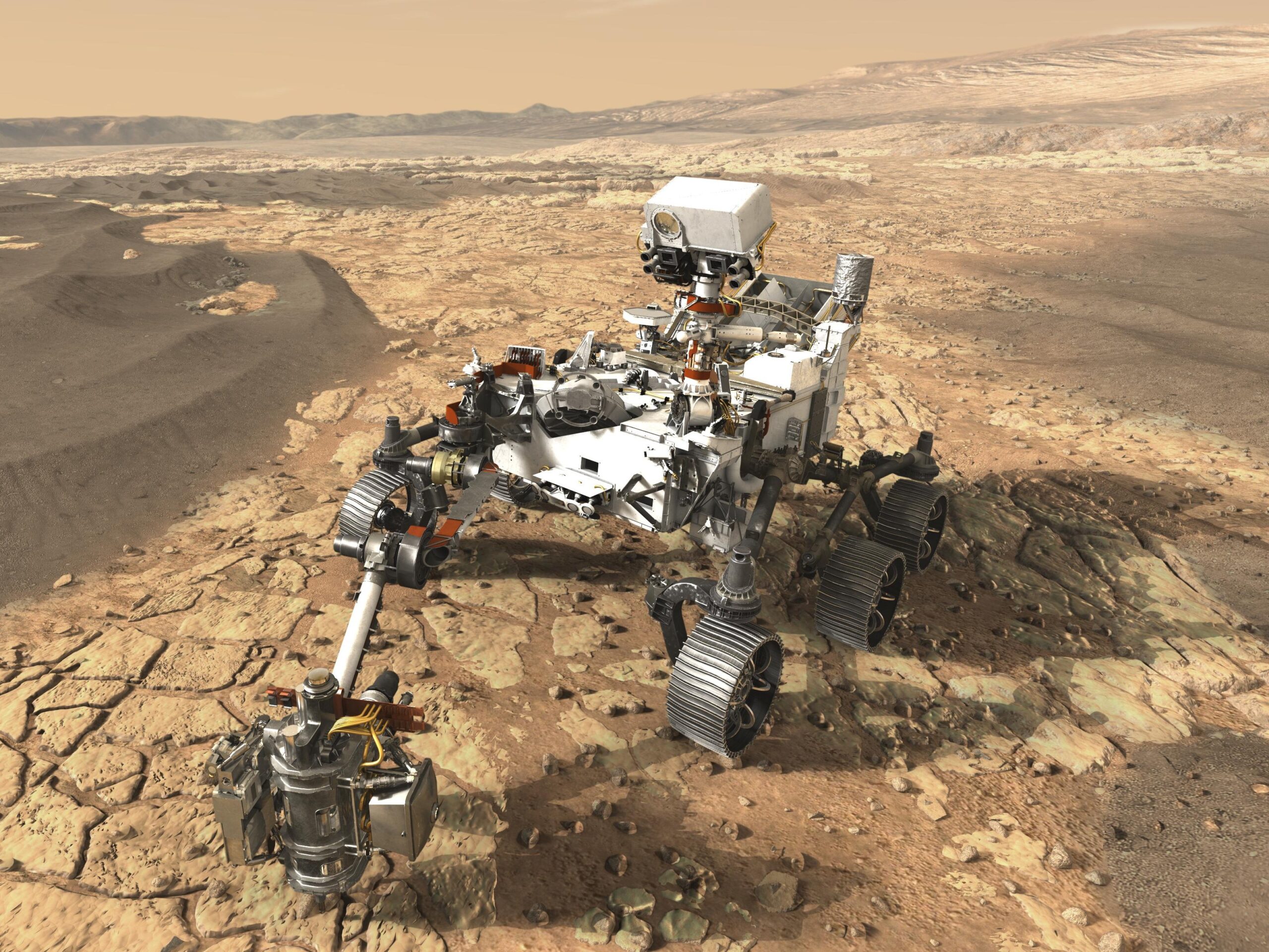

Solving Problems

Provide consulting services in the areas of Tribology and Surface Chemistry, with a specialization in solid lubrication and materials tribology used in space and vacuum applications

Team Support

Provide technical leadership in teams charged with producing robust designs of lubricated devices for critical applications in space and on earth.

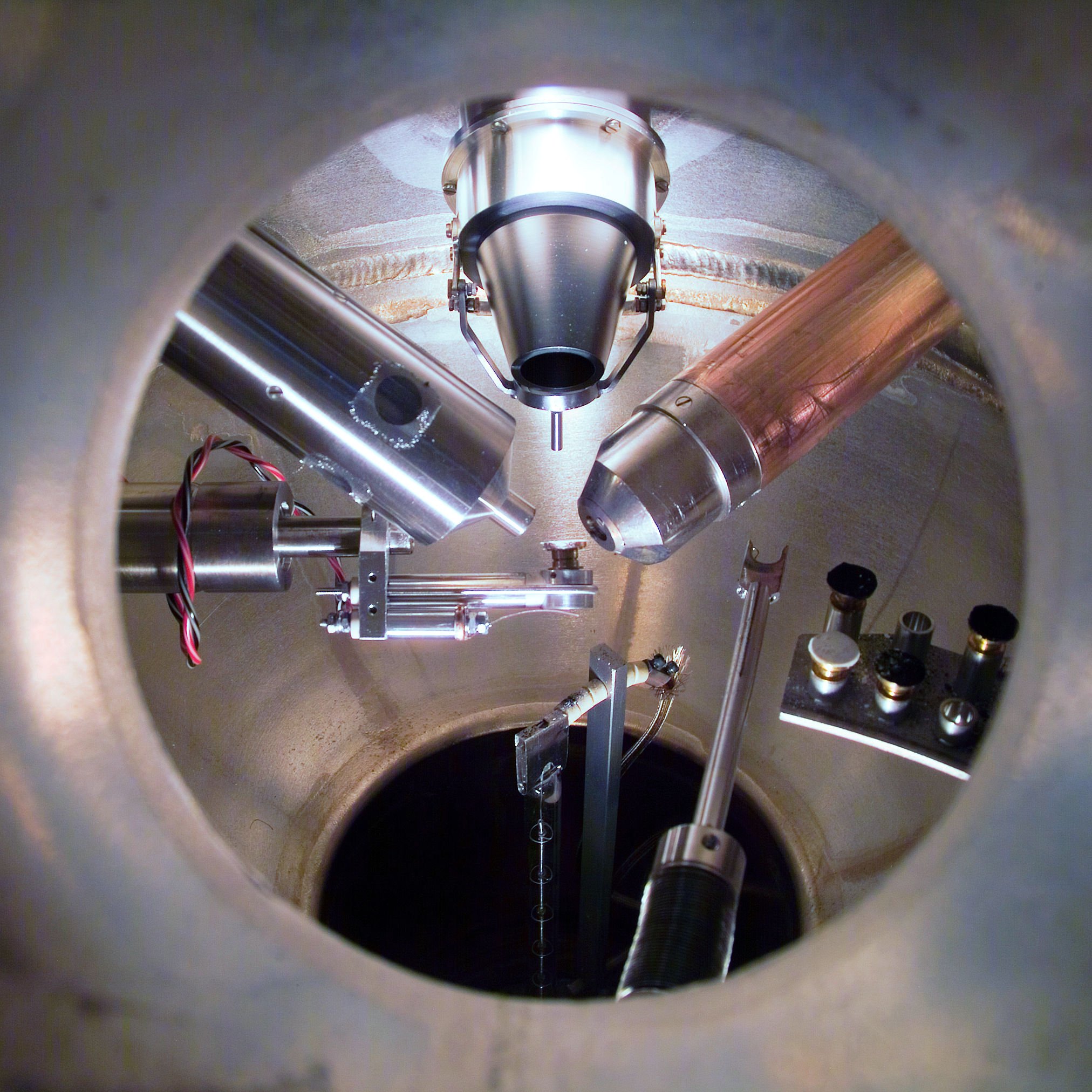

Science for Solutions

Coordinate laboratory investigations for root cause investigations using expertise in analysis techniques in tribology, as well as surface interface, and materials science.